About AMH

Looking for Partner Brands

We want to co-develop early pre-production series with partner brands in order to fine-tune our industrial setup and validate our processes in real-world conditions.

We are actively looking for ambitious brands ready to join us and benefit from a responsive, reliable, and fully European manufacturing solution.

Our factory will be fully operational by the end of 2025, and these initial collaborations will allow us to hit the ground running with premium-quality results from day one.

Don’t hesitate to contact us — let’s build the future of climbing together !

2023/24

2024

2025

End of 2025

Project conception & structuration

Material tests & process validation

Pilot production

Industrial production launch

Made in France • Made for brands • Made to last

Shaping & design

Our shaping workshop turns your ideas into production-ready climbing holds, with deep insight into your creativeness process and with a strong focus on industrial feasibility and efficiency.

We bridge craftsmanship and production to help your brand stand out — from concept to mold.

Tools & process:

- 3D scanning of physical macros or existing shapes

- High-definition 3D printing for ultra-precise prototypes and masters

- CNC foam machining (PU) for fast, repeatable shape production

- Manual shaping for creative freedom and fine details

- Work from your files or collaboratively from scratch

Our added value:

- Shapes are optimized for industrial manufacturing

- Attention to ergonomics, durability, and versatility

- We deliver mould-ready masters, or directly handle mould production in-house

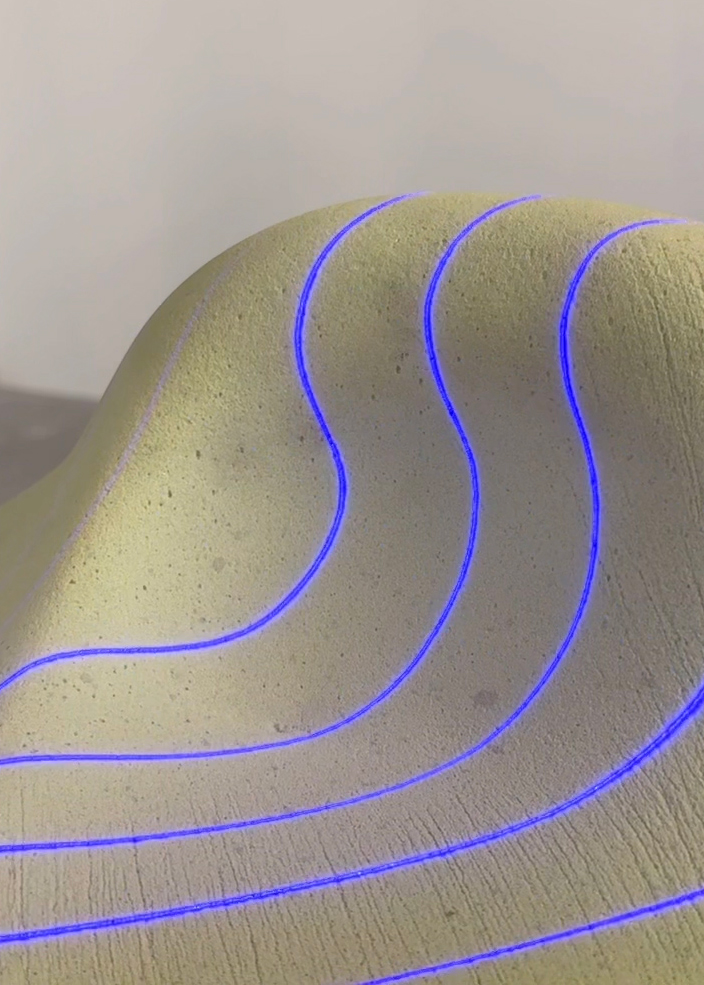

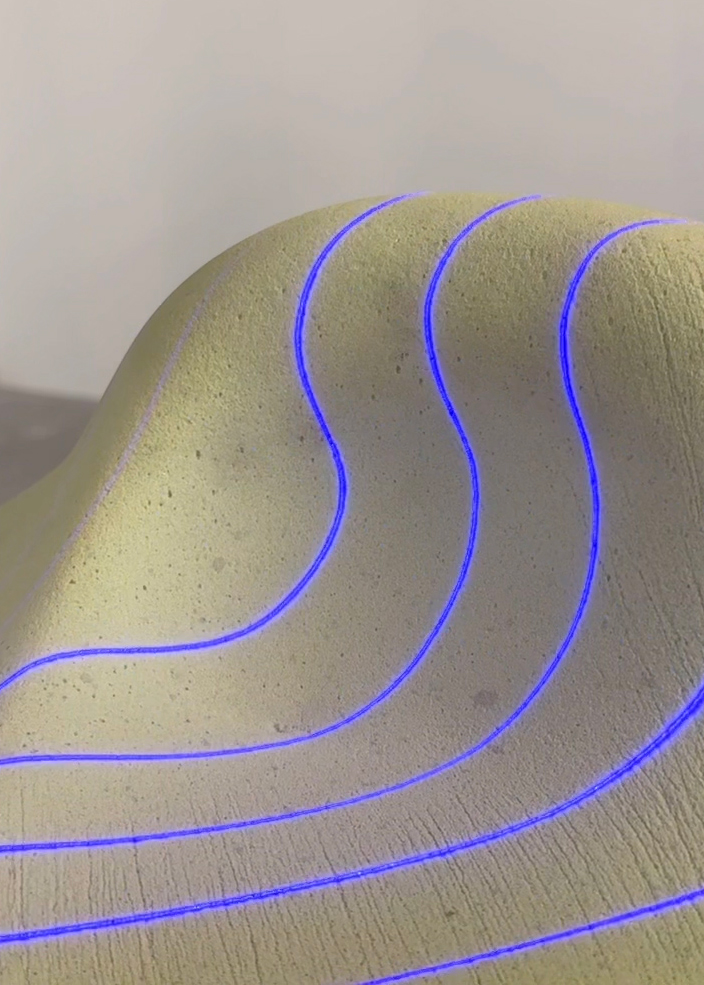

Dual Texture

Dual Texture is integrated from the earliest shaping stage, allowing precise control over friction zones. Industrial-grade coatings are applied to ensure long-term resistance and sharp surface contrast — delivering strong visual impact and unlocking new movement possibilities.

Mould manufacturing

AMH includes a full workshop dedicated to mould manufacturing — a critical step in the industrial production of climbing holds and macros.

We offer several types of moulds tailored to your production process:

- Silicone moulds: flexible, ideal for polyester, polyurethane resins, and fiberglass

- Rigid resin moulds: used for thermoforming or macro manufacturing

- Custom moulds based on your designs or 3D models

- Engineered to ensure durability, detail accuracy, and production repeatability

- Maintenance and reconditioning available to extend mould lifespan

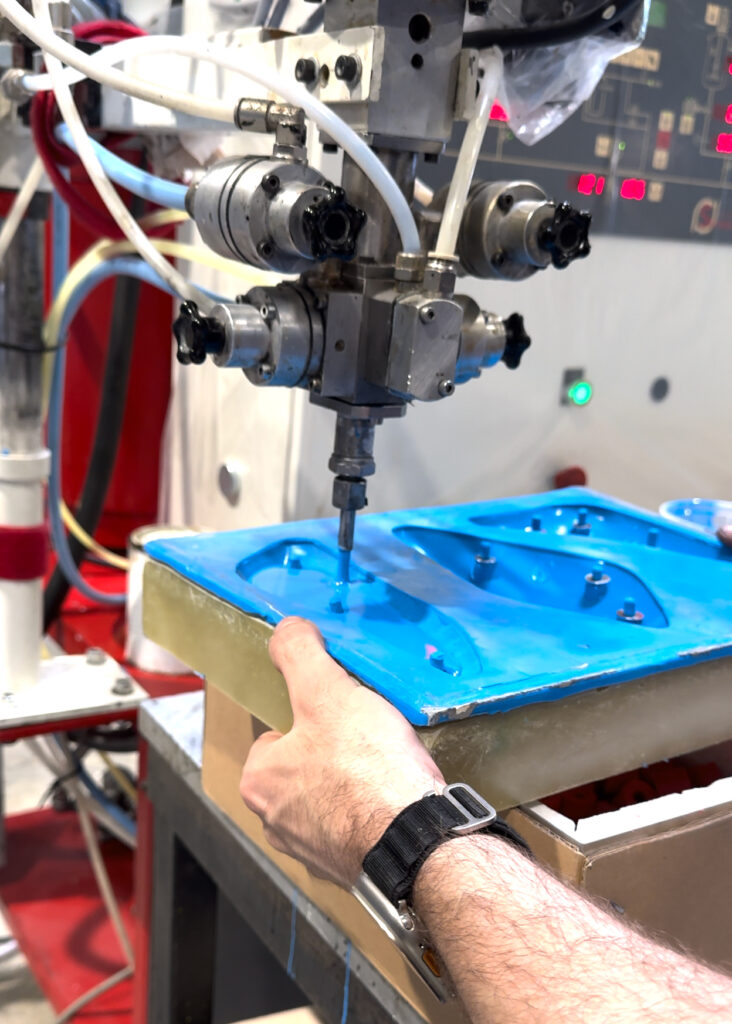

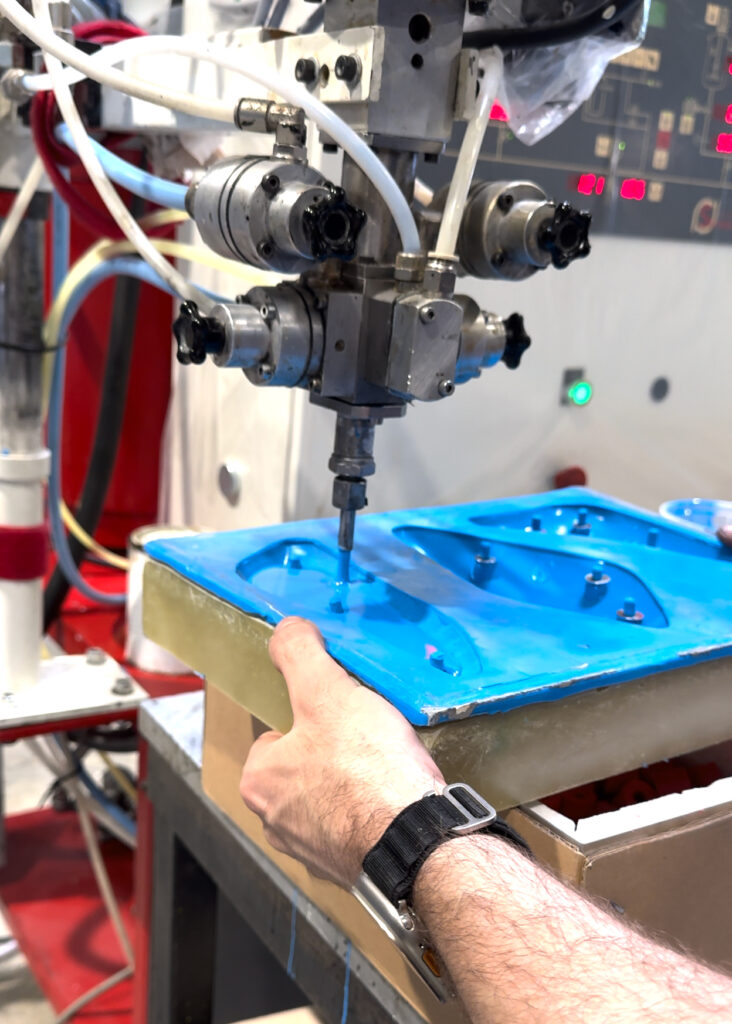

PU climbing holds

Engineered for Durability

In partnership with material experts, we have conducted in-depth research to select and fine-tune a PU formula optimized for industrial use:

- High resistance to impact and deformation

- Long-lasting mechanical performance under heavy use

- Consistent behavior under repeated screwing/unscrewing

- Integrated grain designed to withstand frequent cleaning

- Each batch undergoes strict in-house testing to ensure production consistency and optimal aging over time.

Fiberglass macros

We produce lightweight, strong, and durable macros using a simultaneous spray-up process (resin + fiberglass in one shot).

This industrial method allows:

Precise control over thickness, weight, and overall shape

High structural strength while maintaining lightness

Our macros are:

Reinforced at critical points such as screw holes (wood screw anchors) to prevent cracking and increase lifespan

Coated with a high-performance non-slip texture developed through extensive research to provide lasting grip, even after repeated cleaning and heavy use

Our goal:

to offer a reliable, long-lasting alternative to traditional volumes with optimal handling and climbing comfort.

First brand collab – Ino’Holds x Blokcorp french fiberglass macros

Thermoformed macros

When the shape allows, we produce some macros using thermoforming from recycled ABS sheets – a lightweight, eco-conscious material.

Retexturing & recycling

Traceability system

We offer several types of moulds tailored to your production process:

- Silicone moulds: flexible, ideal for polyester, polyurethane resins, and fiberglass

- Rigid resin moulds: used for thermoforming or macro manufacturing

- Custom moulds based on your designs or 3D models

- Engineered to ensure durability, detail accuracy, and production repeatability

- Maintenance and reconditioning available to extend mould lifespan

Working with us means

🇪🇺 European-based = reduced lead times, carbon footprint and costs

🔄 One single partner for your entire range

💡 Climbing knowledge + industrial precision

♻️ Durable = more sustainable

🔒 No brand conflict: 100% subcontracting

About AMH

AMH is a French factory dedicated to the industrial production of climbing holds and macros for brands.

Born from the synergy between a team with deep roots in climbing and a leading player in composite industrial manufacturing, AMH provides a complete, durable and European-based production tool.

At AMH, we believe in a more responsible, durable and technically demanding climbing industry.

We aim for long-term positive impact for climbers, brands and the planet.

Looking for Partner Brands

We want to co-develop early pre-production series with partner brands in order to fine-tune our industrial setup and validate our processes in real-world conditions.

We are actively looking for ambitious brands ready to join us and benefit from a responsive, reliable, and fully European manufacturing solution.

Our factory will be fully operational by the end of 2025, and these initial collaborations will allow us to hit the ground running with premium-quality results from day one.

Don’t hesitate to contact us — let’s build the future of climbing together !

Made in France • Made for brands • Made to last

Our expertise

Shaping & design

Dual Texture

Dual Texture is integrated from the earliest shaping stage, allowing precise control over friction zones. Industrial-grade coatings are applied to ensure long-term resistance and sharp surface contrast — delivering strong visual impact and unlocking new movement possibilities.

Mould manufacturing

PU climbing holds

At AMH, we produce polyurethane climbing holds with a clear objective: combining lightness, comfort, and long-term durability. PU is the material of choice for high-end lines, especially in bouldering and competition settings.

Fiberglass macros

First brand collab – Ino’Holds x Blokcorp French fiberglass macros

Thermo-formed macros

When the shape allows, we produce some macros using thermoforming from recycled ABS sheets – a lightweight, eco-conscious material.

Retextu-ring & recycling

We offer you the opportunity to retexture your worn and smoothed holds.

This cost-effective technique gives new life to your holds, with durable grip and industrial-quality performance.

Choose an eco-friendly approach by prioritizing upcycling!

Tracea-bility system

Working with us means

🇪🇺 European-based = reduced lead times, carbon footprint and costs

🔄 One single partner for your entire range

💡 Climbing knowledge + industrial precision

♻️ Durable = more sustainable

🔒 No brand conflict: 100% subcontracting